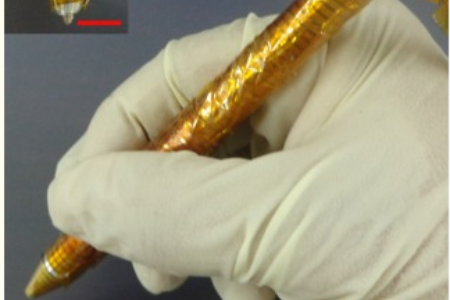

Printing low-melting-point alloy ink to directly make a solidified circuit or functional device with a heating pen

A new method to directly print out a solidified electronic circuit through low-melting-point metal ink is proposed. A functional pen with heating capability was fabricated. Several typical thermal properties of the alloy ink Bi35In48.6Sn16Zn0.4 were measured and evaluated. Owing to the specifically selected melting point of the ink, which is slightly higher than room temperature, various electronic devices, graphics or circuits can be manufactured in a short period of time and then rapidly solidified by cooling in the surrounding air.

The measured melting point of Bi35In48.6Sn16Zn0.4 is 58.3°C, which is slightly lower than the Bi–In–Sn alloys (approx. 60°C). Bi35In48.6Sn16Zn0.4 is a non-toxic material, and the four constituent metals (Bi, In, Sn and Zn) are in widespread use, e.g. Bi compounds are widely used in cosmetics and pharmaceuticals. This metal ink has unique merits such as it is easy to prepare, it has high electrical conductivity, it is non-polluting and it is easy to recycle. Direct writing with such an ink will have important practical significance and application value to supplement the current PCB manufacturing technology.

Metal ink Bi35In48.6Sn16Zn0.4 introduced in this article is an important supplement to the current direct-write technology. Various patterns and circuits can be directly printed in a short time. The electrical conductivity of the metal ink is important in printing devices or circuits. Adding small amounts or nanoparticles of high-conductivity metals is an effective way of improving the electrical conductivity.

Product recommendation:Low Melting Point Alloys

Changsha SANTECH provides Low Oxygen Type Indium Alloys,Low Oxygen Type Gallium Alloys,Gallium Indium Tin Alloy. Please email us if you are interested in our products. Thank you!

EN

EN  AR

AR FR

FR DE

DE JA

JA PT

PT CN

CN