Tellurium recycled from cuprous telluride slag

Tellurium is usually separated as copper telluride slag in pretreatment process of copper anode slime. Copper telluride slag was treated by processes of sulfating roasting, water leaching, alkaline leaching, oxidation, acid leaching, and reduction. The results show that copper extraction rate is 90%, tellurium recovery rate is 91%~93%, and gold, silver, platinum, and palladium are enriched in leached residue. Copper telluride slag was taken from anode slime treatment section of a copper smelting plant in China

(1) Raw materials as test

Copper telluride slag was taken from anode slime treatment section of a copper smelting plant in China

Cu 32.74%, Te 23.12%, Se 2.35%, Pb 1.29%, Au 317.6 g/t, Ag 3.03%, Pt 0.84 g/t

Pd 36.18 g/t

(2) Technical process

Copper telluride slag is treated by sulfuric roasting, water leaching, alkali leaching, oxidation, acid solution-reduction process

(3) Test equipment and reagents

Equipment: KSS-1600 muffle furnace, HDM-1000 heating jacket, 1000 mL flask, JB-90SH stirrer、porcelain boat etc.

Reagents: Analysis of pure 98% sulfuric acid, sodium hydroxide, 30% hydrogen peroxide, sodium sulfite, etc.

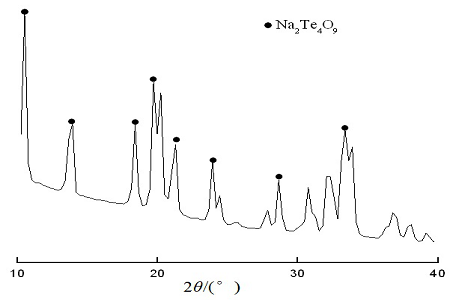

(4) Acid solution reduction tellurium precipitation

A certain concentration of sulfuric acid solution and sodium tellurate precipitation were put together in a four-mouth flask. After the precipitation dissolved, a certain amount of sodium sulfite was slowly added. After a certain time of reaction, solid liquid separation was conducted to obtain the coarse tellurium powder. The XRD pattern of tellurium precipitate is shown in the figure:

Product recommendation : Tellurium

Changsha SANTECH provides Tellurium Metal Ingot, Tellurium Metal Granule, Tellurium Metal Powder, Tellurium Dioxide Powder, etc. Please email us if you are interested in our products. Thank you!

EN

EN  AR

AR FR

FR DE

DE JA

JA PT

PT CN

CN